It has been a while since I posted to this blog. No one ever comments on my posts so that kind of saps me of my motivation to spend a lot of time talking about projects in the garage, but thanks to “anonymous” who posted a gratifying comment this week I decided to post again. It definitely means a lot when I know that my posts are helpful to others out there. Thanks “Anonymous”, you rock!

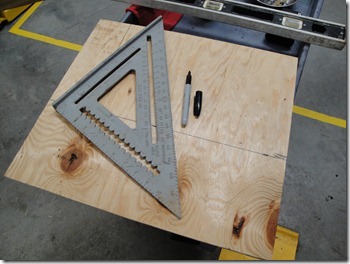

I was long overdue to do some routine maintenance on my old Dodge Ram(2001) so I decided to pull it into the shop this week. Holy cow it took us something like 5 times to get the truck straight into the lift so I decide enough was enough and it was time to put some sort of guides onto the floor. Check this out:

As you can see in the above pics we took some yellow duct tape and marked our parallel lines from the inside of the lift. Because this rotary lift is built with a bit of angle between the posts it is really hard to judge how straight you are as you approach the lift. These lines help TONS when positioning a vehicle in the lift – especially if you have someone standing up front spotting for you. As you know, if the vehicle isn’t straight you run the risk of having one of the arms being unable to reach the frame securely which introduces some hazard to the job.

Doing this was fun and allowed us to practice some math skills at the same time. Each line runs 12 feet towards the garage door from the lift posts. Between the posts, the lines were 92.5 inches apart. Doing some simple geometry, we were able to compute that the end point of each line should be 171.15(if I remember correctly) inches from the opposing start point. Think right triangle! Once we measured everything out we had a perfectly square markup. Next we chalk lined the run and laid down the tape. Easy! If I ever get an epoxy floor, I’ll make sure lines similar to this are painted permanently onto the concrete.

Once I got the truck onto the lift it was time to focus on that routine maintenance. I’ve bought a lot of crap for my vehicles, but it turns out that a lot of it isn’t really crap at all. Check out this oil pan drain plug, for instance.

I got this thing from Geno’s Garage and have not regretted it! The cool thing about it is that it has a perfectly secure seal until you are ready to drain the oil. One simply pushes the lever out of the notch and moves it to begin draining the oil. There is absolutely no risk of stripping the threads in the pan.

The best thing about this drain plug? No oil stained hands as you remove a plug during the last few threads.

The best thing about this drain plug? No oil stained hands as you remove a plug during the last few threads.

Another great addition to the truck? Mag Hytec differential covers. This one for my rear differential, for example:

The great thing about these things is that they come with a very high quality dip stick to help you determine not only the quantity of lubricant, but the quality as well. I pulled this stick today and discovered some really dirty looking fluid. Draining it was easy because of the drain plug on the bottom.

The great thing about these things is that they come with a very high quality dip stick to help you determine not only the quantity of lubricant, but the quality as well. I pulled this stick today and discovered some really dirty looking fluid. Draining it was easy because of the drain plug on the bottom.

Fast Coolers. This truck has a 6 speed manual transmission on it. I installed some Fast Coolers on it a while back and while I have no idea if they have helped curb transmission temps I do feel more confident pulling the 5th wheel knowing that they are there.

I do have one complaint though. There is no dipstick to gauge fluid level. On the top of the right cooler there is a fill plug with a magnet on the end but because it’s not really in the fluid it doesn’t really pick up any metal. I came really close to pulling it all apart today to clean up the internal magnet but decided against it for now. I did drain it and will fill it with fresh oil this week as soon as it arrives.

I do have one complaint though. There is no dipstick to gauge fluid level. On the top of the right cooler there is a fill plug with a magnet on the end but because it’s not really in the fluid it doesn’t really pick up any metal. I came really close to pulling it all apart today to clean up the internal magnet but decided against it for now. I did drain it and will fill it with fresh oil this week as soon as it arrives.

OK, so to the questionable shop practices issue. A few weeks ago I did a brake job on my G35.

As I was working on the car everything was going really well until I took out the old pads and noticed something suspect on one of the pads from the drivers side:

As I was working on the car everything was going really well until I took out the old pads and noticed something suspect on one of the pads from the drivers side:

Does anyone see a problem with this picture? Here is the pad from the other side:

Obviously the drivers side indicator has been bent to produce the typical sounds associated with a worn pad much sooner than it should produce those sounds. The question is, was this a factory defect or was this bent in the shop. I took the car in for routine maintenance early after purchase before my garage was constructed, so I wonder. Obviously I could have waited to do this job 10 or 15 thousand miles if this defect wasn’t present.

Obviously the drivers side indicator has been bent to produce the typical sounds associated with a worn pad much sooner than it should produce those sounds. The question is, was this a factory defect or was this bent in the shop. I took the car in for routine maintenance early after purchase before my garage was constructed, so I wonder. Obviously I could have waited to do this job 10 or 15 thousand miles if this defect wasn’t present.

Anyway, that’s it for now. Stay tuned for an update that includes some home improvement work that is going on here. Thanks for reading! Wayne